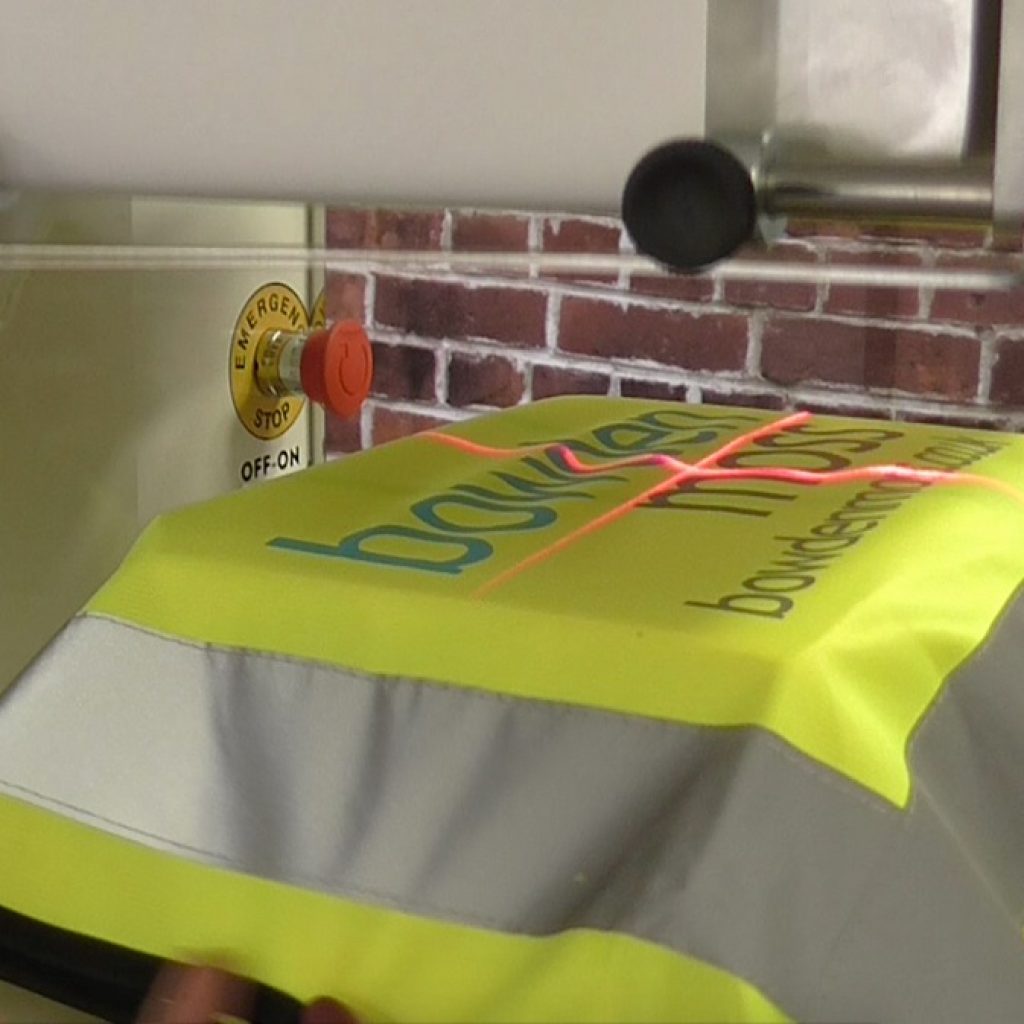

The industry leading semi-automatic heat transfer presses capable of over 500 multi-colour prints per hour!

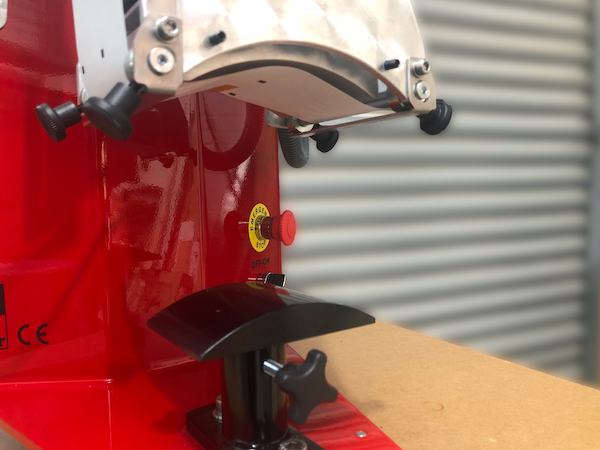

InnoPrinter® for Caps: Semi-Automatic Cap Transfer Press

Print baseball caps in under a second with multi colour designs.

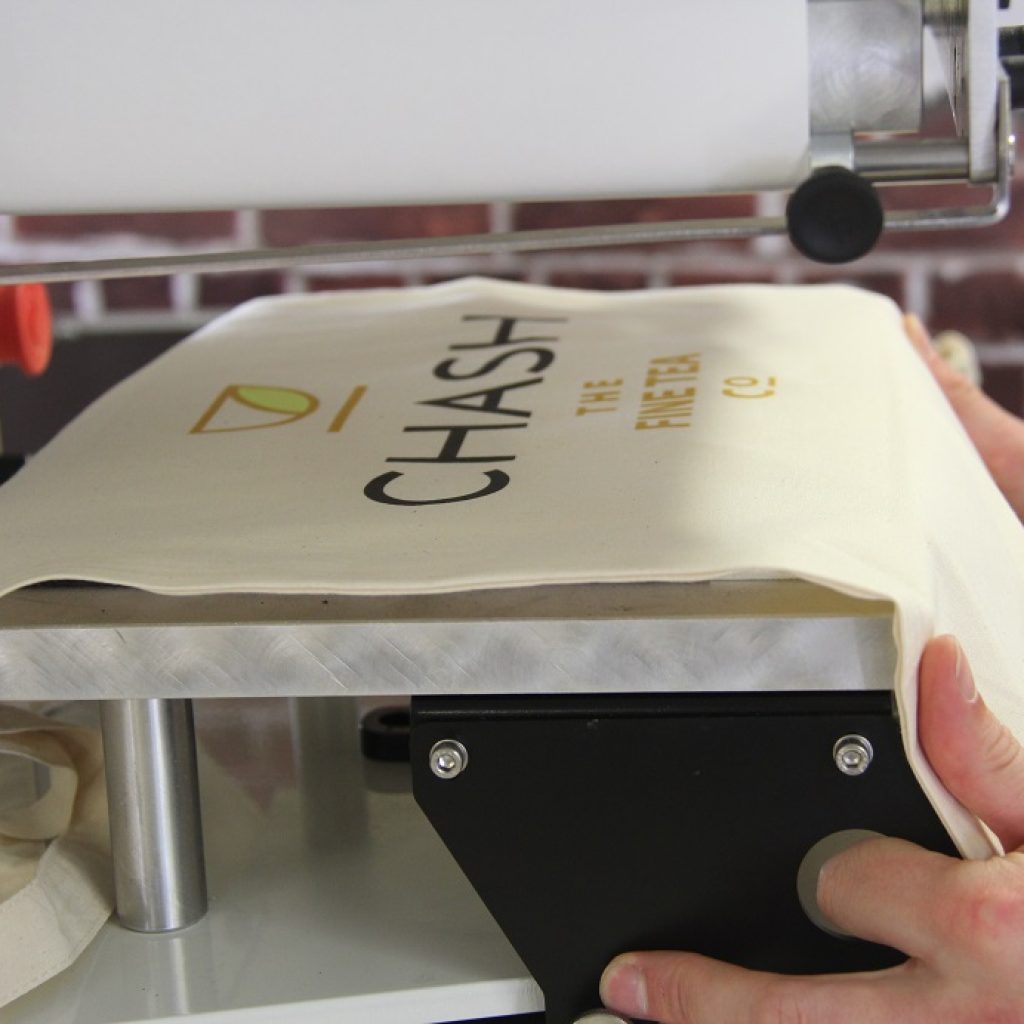

This purpose built InnoPrinter® semi-automatic heat transfer press machine offers headwear decorators a revolutionary way to print high quality designs directly onto curved items in less than a second.

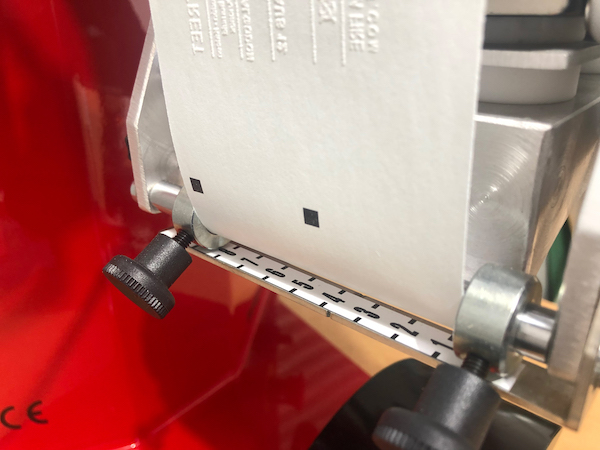

The innovative ‘continuous-roll’ system enables workers to print 4 colour designs onto a broad range of fabrics with minimal training or experience.

The curved heat plate and worktable allow for a maximum printable area of 100x80mm. This InnoPrinter® is an extremely versatile heat transfer press, not only perfect for baseball caps, but virtually any compact flat or curved textile product.

Accurate. Economical. Efficient.

- Easily accessible curved pressing area

- Simple foot pedal operation

- Fully programmable application settings

- Auto-adjusting pressure control system

- Optical transfer registration

- Skin detection safety system

- Easy-alignment loading process

- Minimal space required for operation

- Low energy application

Machine Features

Curved heat plate & magnetic worktables

‘Continuous roll’ feed system

Instantly cured multicolour prints

Skin-detection safety system

Optical sensor alignment

Foot pedal operation

Manual & automatic modes

Solid cast heating elements

Simple operation & maintenance

Compact space-saving form

Operating Specifications

Operating Temperature

25- 230°C / 77-445°F

Display Timer Range

0.5 – 60 seconds (+ 0.05 sec)

Maximum Print Speed

720 prints/hour

Maximum Head Pressure

5,400 Nw (560kg)

Maximum Textile Thickness

10mm

Technical Specifications

Maximum Print Area

100 x 80mm

Power Consumption

350W, single-phase (AC 230v 50-60Hz)

Compressed Air Consumption

60 litres/min @ 4 bar

Physical Dimensions

450 x 550 x 750mm

Machine Weight

65kg

Worktables inc.

Curved 100x80mm

Optional Accessories

Laser positioning guide

Warranty

2 year manufacturer warranty

(exclusions apply)

A selection of accessories are available across the range of InnoPrinter® heat press machines.

Magnetic Worktables

The table below which size magnetic worktables are supplied as standard with each InnoPrinter® model.

| MK1 | MK1-Caps | MK2 | MK3 | MK4 | |

| 100x60mm | • | • | • | • | |

| 100x100mm | • | ||||

| 100x80mm (curved) | • | ||||

| 120x140mm | • | • | • | ||

| 260x170mm | • | • | • | ||

| 350x240mm | • | • | |||

| 400x300mm | • |

Custom sized and/or shaped worktables are available upon request.

Silicone Foam

In order to maintain the highest print quality, the InnoPrinter® system uses repositionable magnetic silicone foam to focus its heat and pressure across the smallest possible area.

The foam pieces can easily be cut to shape using a blade or pair of sharp scissors.

The strong magnetic backing allows the pieces to be accurately positioned on the worktable, without the risk of movement during pressing applications.

Silicone foam pieces are available in the following standard size: 100x60mm, 100x100mm, 120x140mm, 260x170mm, 350x240mm, 400x300mm & 500x500mm

Laser Positioning Guide

Available as standard on MK2, MK3 and MK4 InnoPrinter® models, or as an optional extra on the InnoPrinter® MK1, the easily adjustable laser positioning guide simplifies garment alignment and increases productivity.

The twin-axis laser guides provide the operator with clear point of reference when determining where to apply prints in relation to landmarks such as seams, pockets, zips and buttons.

Bambi Ultra Low Noise Oil Free Air Compressors

The InnoPrinter® system operates best when supplied with a clean, oil free supply of compressed air.

We’ve teamed up with Bambi Air to offer their PT range of ultra low noise oil free air compressors along side our InnoPrinter® semi-automatic heat transfer press machines.

InnoPrinter® Semi-Automatic Transfer Presses

Online Video Demonstration

Visit us in Bedfordshire

On-Site Demonstrations

Slots get booked up quickly so be sure to get in touch ASAP.