Joining a new industry can be daunting, whether it’s to learn about it as a consumer or as a potential entrant to the market. It must be unnerving when you hear words you don’t know the meaning of, which is a major reason why some new entrants struggle in the screen printing industry. There are some screen printing terms you should know to get started with your journey, so here’s a glossary of common phrases and words used in the industry that we’ve tailored for the new guys on the block.

A

Abarade – excessive wearing down/scrubbing, which results in a rough texture on the surface.

Artwork – the design set to be printed on a garment and ready to go on the screen.

B

Bleeding – when ink migrates out of your desired printing area, resulting in dye migration.

Blend – printing two or more inks simultaneously to create a gradient effect.

Block-out – A liquid similar to emulsion that prevents ink passing through the screen where it doesn’t need to.

Burn – Exposing an emulsion-coated screen to create a stencil using a light source.

C

Capillary film – The film used for the stencil. This is light sensitive; therefore, there is the need for exposure from the light source.

Coating – the term to apply emulsion to the mesh on a screen, which is completed using a machine.

Conveyor dryer – A heat source that can cure inks for a period of time; this uses a conveyor belt to pass the garments through.

Colour composite – the artwork rendered in its exact form of how it’ll appear on a garment, which means you’ll see the final result on screen.

Coverage – the amount of ink and quality laid down on a garment through screen printing.

Curable Reducer – liquid added to plastisol ink to ‘dilute’ and thin the ink (viscosity).

Cure – a heat process used to fuse ink.

Cured emulsion – emulsion that has been exposed to light.

Cured ink – when ink is put through the oven to dry and bond to the garment’s fabric.

Cut lines – vector lines that are converted into cut lines using software, so a vinyl printer can form lines in the vinyl for the design. In other words, the machine knows what shape to create.

D

Darkroom – a room that (is dark and) lacks light frequencies used to expose emulsion so that screens can be created and coated.

Degrease – generally cleaning of screens using a cleaning solution before emulsion is coated.

Dehaze – a cleaning solution used after emulsion remover has unsuccessfully removed all the emulsion from a screen. It is a more aggressive chemical that should fully restore the screen.

DPI – dots per inch. The higher the DPI, the higher the resolution. Used to measure spatial printing or video dot density.

Durometer – measurement used to determine the hardness of squeegee material. The higher the number, the harder the material is.

Dry mesh – mesh that is tinted in a single colour (various colours such as yellow, amber, purple) to prevent transmission of light.

E

Emulsion – a light-sensitive chemical applied to screens to make a stencil.

Emulsion remover – to reclaim a screen by adding a chemical solution over a slightly soaked screen to absorb into the emulsion, ready for removal.

F

Flash dry – ink dry to the touch but not cured.

Flocking – a printing process. The flock material is applied after plastisol glue is printed onto the fabric, giving a velvet texture.

Foil – a print process similar to flocking, except the foil material is used instead, to create a mirror effect.

Four-colour process – A printing technique and colour process used for software. Also known as CMYK (cyan, magenta, yellow and black, the KEY colour).

Flood – the process of spreading the ink over the screen and pushing it through.

H

Half-tone – a grayscale or colour image converted into dots (small or large).

Halftone dot types – various shapes of halftone dots, with circle dots being the most common (square, line, diamond and elliptical can be used).

Heat press – a machine that sticks transfers down onto a garment to be peeled, using heat and pressure. Can come in automatic and manual types.

Heat platen – the plate where the garment rests on while being pressed. Some heat press machines have adjustable platens for different sizes.

I

Infrared – energy wavelengths that produce heat using IR radiation.

O

Off-contact – a type of printing where the screen doesn’t have contact with the garment or the platen itself and instead hovers over it.

Over printing – printing a colour on top of a previously printed colour, in other words, an additional layer.

M

Manual press – screen printing industries generally use this press to manually add pressure to a transfer on a garment.

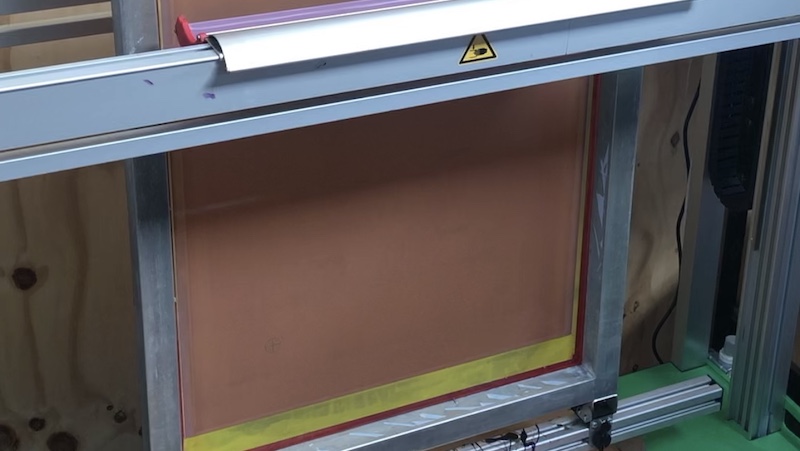

Mesh – the material on a screen frame where the emulsion is coated, ready to make a stencil.

Mesh count – the number of threads in one square inch of the screen fabric. If the number is lower, it means the mesh is thicker. If the number is high, the thread is finer.

P

Plastisol ink – ink that sits on top of fabric, without soaking into it.

Pinholes – specs that appear in stencils after they have been exposed. Usually unwanted and require covering up.

PMS – The pantone matching system used to mix various inks to achieve a colour specific to a pantone reference, which can be found in updated versions of the book.

Positive – Media used to fully block out UV light during the exposure process.

R

Reclaim – to remove emulsion from a screen so it can be reused for another job.

Registration – Lining up a screen image to the original art to separate on a printing press.

Re-tension-able frames – specific frames with capabilities of securing the mesh on a screen frame without added security of stretching equipment.

RIP – raster image processing. Refers to digital software that works with pixels as opposed to vector lines.

S

Safelight – a light used specifically for light-sensitive tasks like emulsion or capillary films to avoid UV light exposure.

Squeegee – a tool made out of wood or metal with a blade used to push ink through a stencil, using a pulling and pushing motion across the screen.

Spot colour – a colour premixed in a Pantone reference, ready to use.

Stencil – the exposed section of a screen where the image will be printed.

Step wedge test – exposure test that determines how much exposure is needed for a screen.

Stirring stick – a wooden or plastic stick to stir emulsion before coating.

Substrate – a term allocated to the garment that will be printed i.e. ‘the t-shirt is ready for print’ is the same as ‘the substrate is ready for print’.

T

Tension – measure in newtons. The tightness is referring to the screen mesh placed on the screen frame.

U

Underbase – the first coat of ink applied to act as a base for the other colours, usually needed for multi-colour designs on colour t-shirts.

Underexposed – when a screen isn’t exposed enough, the stencil can become soft, resulting in break down.

V

Vector – a term used for software that works with lines as opposed to pixels, capable of stretching to any size. Also can be converted into cut lines and works well for precise vinyl cutting.

Viscosity – the thickness or thinness of ink.

W

Wash test – after a garment has been printed on, this is usually a test run in the laundry to determine if the print is durable or not.

Washout booth – the booth used to wash our stencils and clean screen printed emulsions.

Water-based ink – ink that soaks into the fabric, rather than sitting on it.

Weeding – the process of removing excess vinyl from a design using the cut lines as a guide.

And there you have the basic terms used in screen printing, as well as some that are more complex. For instance, you may not come across unless you plan to work with that specific type of screen printing, however it is useful to know! If you need transfers to get started with, Innotex Transfers can supply FREE samples for you to check out!