Are you investing in a heat press machine or just curious about the capabilities of heat transfers for clothing? If so, this blog contains all the information you need to make an informed decision. And if you’re not fixed on heat transfers just yet, check out our pros and cons. Yes, we’ve got that covered as well!

What is a Heat Press Machine?

Heat transfers refer to the process of using transfer paper and a heat press to transfer prints to garments. This requires certain temperature, pressure and timing to successfully achieve and create a long-lasting product. Some of your printed garments have gone through a heat transfer process in some way. This includes whether it’s been ironed on, heat pressed, or even sublimated (we’ll get onto that later).

As mentioned above, you need a machine to give your product a finished result. This is because without a heat press machine, you’d have to manually iron on your transfer. In other words, your transfers won’t be high quality if you use a hand iron. It is recommended that heat press machines are preset to a max temperature of 175ºC. They should be pressed onto the garment for about 5-10 seconds. Any longer and you’ll risk scorching the garment.

Different Types of Heat Press Machines

There isn’t one universal heat press machine that does everything. You’ll find there are various kinds that can be used, some suitable for one project, some for another. This doesn’t mean you need to invest in 4 different types of machines for your needs, this is based mainly on convenience rather than capabilities. Let’s take a look at each type of machine and find which one is best for you.

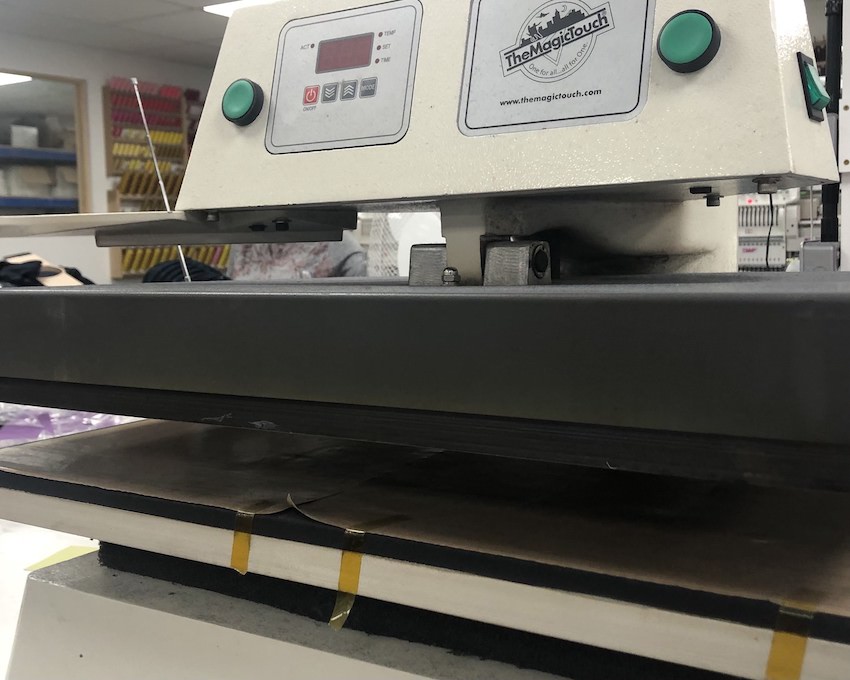

The Clamshell Heat Press Machine

This one is self-explanatory; its movement mimics that of a clam. The machine is hooked by one end which allows the motion to take place smoothly. Garments can easily be “stamped” for about 5 seconds without having to do anything else. If you’re new to garment printing, this machine is great as there’s not much to learn in a technical aspect. This machine isn’t large at all (which is great for portability), so if you’re intending to print transfers of a small to medium size, this machine will work for you.

The Draw/Pull-out Heat Press Machine

Now we’re onto the machine with added space. The draw machine is also referred to as the pull-out machine because it has the capabilities of added workspace. Pull-out machines have an adjustable lower platen that allows you (for the most part) to lay the garment over the other side, so you only need to work with the specific section you need to press. By allowing the garment to hang over the other side, there’s less worry about needing a massive machine to place the entire garment over. You’ll also benefit from the full view of the heat press surface, without having the mechanism blocking your view.

The Swing Away Heat Press Machine

To be honest, most of these heat presses sound self-explanatory. You probably already guessed that this machine has a lot more movement involved, with the heat press swinging away with every use. This machine is quite heavy, unlike the clam machine; though it pretty much sounds like the opposite motion (side to side instead of up and down), the movement occurs between 180 – 360º, so you’ll need more room to carry out projects. Another thing to note: this one is HEAVY, so it’s not portable. On the bright side, this machine requires even less manual labour, so you can let it do most of the work for you.

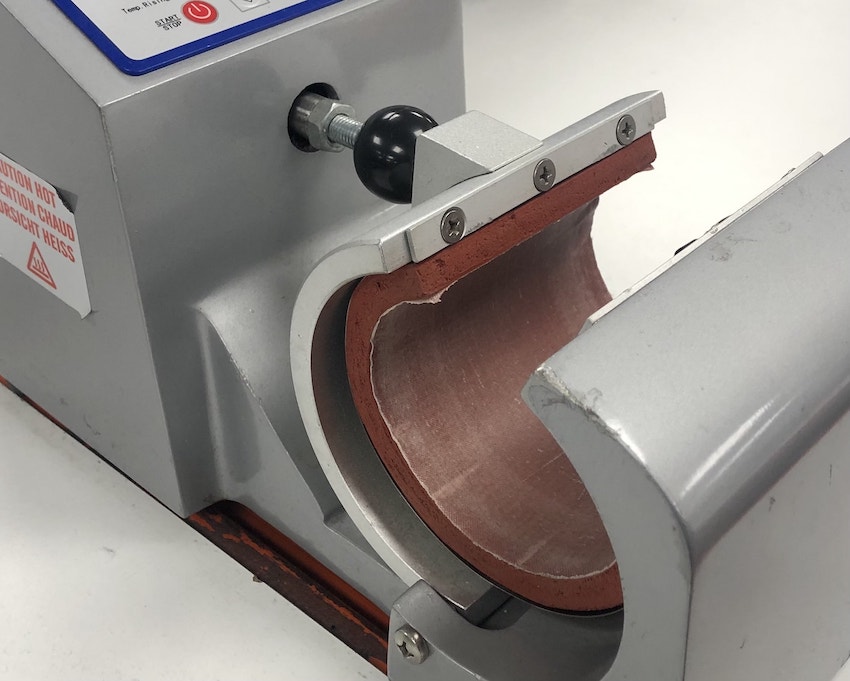

The Sublimation/Mug Heat Press Machine

Finally, one that I get to fully explain without you guessing! This machine is not like the other heat press machines. For one, it isn’t limited to just garments, you can also heat press on mugs, hats and more! It’s your choice – you can use a standard heat press machine, (so any of the 3 mentioned above) but the added capabilities of sublimation printing require a specific machine, shaped to place mugs and caps in to avoid damaging the product. If you need to sublimate objects, you need a sublimation heat press machine, no doubt about that. you just need to sublimate garments, a specific machine isn’t suitable as you need a standard flat surfaced heat press machine (but at least it gives you more options). However, if you need more information on the process of sublimation, check out our blog on how to avoid dye migration!

The Pros and Cons of Heat Press Machines

Now that you’ve got an understanding of producing heat transfers for clothing (and objects), it’s time to dive into the detailed pros and cons of each machine.

Clamshell Machine

Pros

Cons

- They are easy to use for beginners and don’t require a lot of technical information and there aren’t many moving parts

- The machine is generally small which makes it portable (great for taking around to different locations without limiting yourself to one area)

- It’s one of the cheaper types of machines in the market, varying between £1000 – £2500, depending on size and additional settings

- The electricity output is a lot less than the average heat press, due to limited movement and surface area to heat (cost effective)

- You don’t need a lot of space to use this machine as the machine’s movement is up/down

- The heat press process for clamshells requires regular contact with the machine surface, meaning there is a higher risk of getting burned (wear gloves!)

- Printing thicker garments will be more difficult as the heat press is generally designed as a dinky product for light work. Thin garments like t-shirts and lightweight hoodies are more suitable, rather than heavyweight hoodies

Draw/Pull-out Machine

Pros

Cons

- More capabilities than clamshell as it allows for more space by pulling out the platen to place garments on

- It’s also another cheap machine on the market, varying between £160 – £1000, depending on additional capabilities and size

- The machine has a unique hydraulic mechanism in place to allow for a smoother opening/closing motion

- Pull-out machines can transfer prints for both thin and thick garments, ideal for small and large enterprises

- There is more adjustment required when working with this machine, so it’s not capable of adjusting the settings automatically

- The electricity output is a lot higher, which means it is less efficient and has a bigger bill

- It’s adjustable platen can move easily at times, so even though it has the added capability, it has added risk

Swing Away Machine

Pros

Cons

- The machine allows for full view of the surface area, which is more convenient when working with larger garments

- Swing-aways do most of the work and you don’t have to adjust much with a swing away machine

- The swing away machines are less hazardous in terms of manual labour – since there isn’t much work required, there’s less risk of getting burned

- The 180-360º swinging motion means it takes up a lot more space than the clamshell which moves up/down. The larger the machine, the more space you need

- It’s not a portable machine, so wherever you place it, it’s recommended to keep it there

- The pricing is a lot higher for the machine, varying between £1,600 – £5000

We also have a guide on Transfer Paper for Heat Press Machine

Sublimation/Mug Machine

Pros

Cons

- This machine is completely different to the previous 3 – it allows for printing on objects such as mugs and caps

- The process for sublimation heat transfer is quite easy, similar to the clamshell machine, the mechanism moves up/down

- Swing away machines are generally smaller since they’re designed for small objects, which means they’re portable

- One of the cheapest machines, varying between £160 – £800. It has the added capabilities but is also limited

- The sublimation machine can’t do all types of sublimation printing as garments sometimes require sublimation (this machine is made for objects, not garments)

- Pricing is a lot higher for the machine, varying between £1,600 – £5000

You might also like: How to Use a Heat Press Machine for T-shirt Printing

So Which Heat Press is Best for Me?

All of the above information covers all the necessary information you need to decide which heat press machine is best for you, but you may still need a bit more advice on which one will suit your company – that’s what this section is for!

Budget

We understand that budget is sometimes not a concern, so it’s not really a deciding factor, but sometimes the budget is the primary cause for a purchase. If you’re starting out in the industry or you print on demand, a clamshell machine would be best for you. This is the beginner machine and is usually the go-to for quick and easy transfers. The budget is flexible – you can buy a really cheap one that has the same capabilities as expensive ones, but you’ll be limited in size. Even so, the smallest machines are usable (as I said before, most of the decision-making is based on convenience).

Area

If you’re looking for a machine that gives you more space, but you don’t always need it, the draw/pull out machine is perfect for you! This machine allows you to place your garments on with more ease but also gives you extra space if required. If you’re working with both small and large garments, a clamshell would not be as easy to use. Generally, the draw machine is used for small and large businesses and has flexibility for your budget – the sturdier and larger the adjustable platen is, the more expensive they get.

Number of Orders

If you have a large workspace and a higher budget, the swing away machine is great for large orders. The machine pretty much does everything for you and allows you to work with a full view of the workspace, so you know exactly what’s going down during the production process. These machines are generally more expensive than standard heat press machines but depending on how reliant your business is on the machine to put in the work, it can be worth the investment!

Type of Final Product

And lastly, if your business also expands into sublimation printing (and not just on garments), sublimation heat press machines are a must-have because there’s no other type of machine that can produce transfers on objects. But don’t worry – they’re not expensive at all! However, if you need to sublimate garments, you’ll need one of the heat press machines mentioned above, on top of a sublimation machine.

Is There an Alternative to Using Heat Press Machines?

Technically, yes there is. But they aren’t considered a professional tool. If you’re just starting up a business from the comfort of your home, you can use a clothing iron to ‘heat press’ your transfers onto your garments. However, it’s not recommended because industry machines are made for the purpose of having high-quality prints and durability – something that can’t be guaranteed with a clothing iron. The specifics of temperature, timing and pressure vary when it comes to clothing irons, so this is pretty much a last resort. As mentioned above, iron transfers are mainly completed on t-shirts, so you’d need a t-shirts table for heat pressing (ironing boards are not secure enough).

How Can Innotex Transfers Help Me Further?

So to wrap things up, are you a small business or a large business? Do you have a low budget or a high budget? Are you new to the industry or familiar with it? Either way, there’s a heat press out there with your name on it.

Now if you need a supplier to provide you with ready-to-press transfer prints, Innotex Transfers has competitive prices to get your orders to you within a current lead time of 5 days. Bulk or small orders, we’re here to help! Don’t hesitate to email us at sales@innotextransfers.com or call us at 020 3617 8710.